Fast

Rapid prototyping is fast by definition, having 3D print capability in-house will make you more productive provided the operation of the printer is not a task in itself.Rapid prototyping or production is more than just print speed.

To compare 3D printers in terms of speed we need to look at setup, operation, print speed; linked to print quality, success rate and, of course, cost because two low cost printers can outperform a single more expensive one.

Robox design, from weight of the motion parts to the streamlined 3 click print setup, is focused on quickly achieving each print job at high quality. The design of key parts and the underlying systems show very clear gains in completing jobs faster than any other 3D print system.

The printer comparison link below takes you to a very detailed and sortable list of the best dual extrusion printers on offer.

Accurate

Tolerance is part of any mechanical design and has an impact on usability of the produced component. 3D printers can produce very accurate motion and positioning of materials.But reaching an acceptable tolerance does not end there

Materials expand and contract with thermal changes, a controlled build chamber is the best way to reduce the effect on part construction, highly repeatable results allow for design adaptation in a loop which ensures the best possible outcome.

In Robox where there is potential for inaccuracy there are novel devices and tools built-in to compensate for this and tune systems for repeatable accuracy. As mechanical engineers CEL-UK have ensured that every step in design, construction and usage of Robox ensures the best possible accuracy while retaining the core need for a machine which is easy to procure, maintain and operate.

Reliable

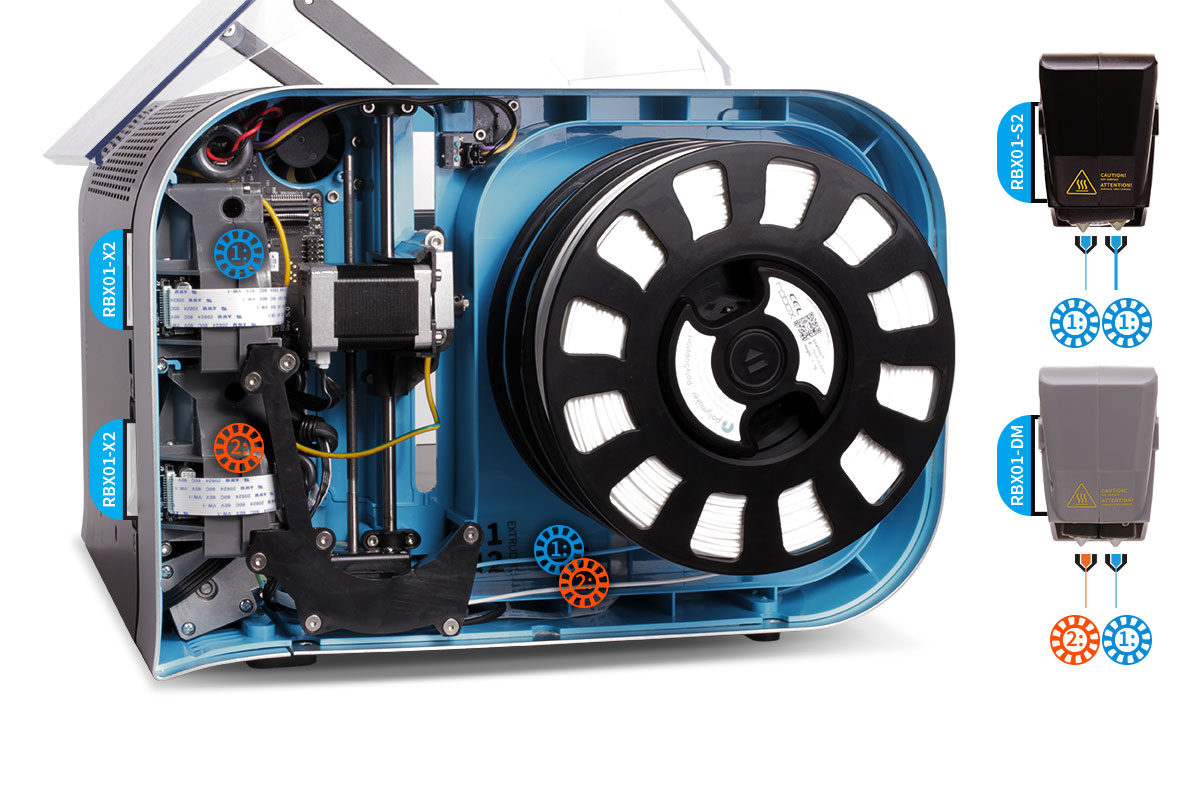

Modular design means that the hardest working parts can be swapped out in seconds without tools.Designed for business

Smart monitoring appeared in Robox machines first and provide a software alerts and automated systems that prevent hardware damage.

Our motion frame design is the same as large format CNC because it is extremely rigid to ensure relationships between axes are maintained. Speed is a priority so a low weight of motion parts is critical to allow the best acceleration potential. Stationary and slow moving parts are precisely machined stainless steel. Electronics are designed specifically for our system right down to custom stepper motors, this ensures there is no load problems or incompatibility.

Backing this up is a best in class warranty on all parts including consumables and our excellent UK based customer service.

Efficient

Material usage, success rate, time to set up, time to print, effect on productivity, resource availability.Additive Manufacturing is more efficient in terms of material usage than traditional subtractive methods such as CNC machining.

AM also allows shapes and structures which are impossible using other methods. As a technology it is easy to access and low cost machines can achieve complex shapes accurately without a labour cost as the machinery runs through program without supervision.

Robox systems have won awards for ease of use and our dual extrusion systems save between 10 and 30% material with every job.

Cost Effective

3D printers have dropped in price significantly since a patent expired in 2009. Many remain significantly over priced for the value offered.Finding the right balance between expensive and cheap is about trust

At the bottom end there are hundreds of unsupported copies of copies of the basic frame and extrusion systems, many of these can produce nice looking models but will not be capable of printing in materials with desirable mechanical or chemical properties. Mid-high cost printers are a big jump from the bottom end in terms of pre-configured setup, support and per-print success. The high cost printers are being challenged by this mid range.

RoboxDual will outperform any printer even 10 times the price. For a larger printer with the same capabilities RoboxPRO is feature rich and has a very large build capacity.

Innovative

We made 3D printing

faster, more reliable and easier.